Automotive

Application Server

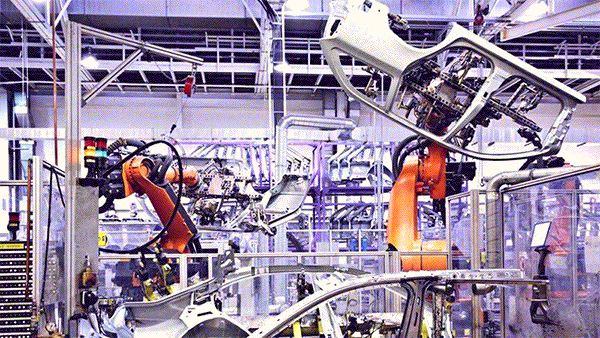

AVEVA software solutions offer a variety of advantages to achieve the overall business goals of automotive companies. Firstly, the technology can easily integrate with existing equipment and programs from various external suppliers on-site. The integration approach enables the synchronization of industrial and production operations, providing the speed and flexibility necessary for sustained profitability and continuous growth.

Another key advantage is the ability for managers and operators to transfer data easily and quickly between manufacturing automation systems and ERP systems. This allows for improved production performance and on-time deliveries with more accurate and real-time information for production planning, execution, and order fulfillment.

By linking the production process with the ERP system, the company can analyze its overall operational performance through simple yet powerful data analysis and reporting tools. Additionally, integrating the AVEVA Select Apu solution with ERP systems allows for customer order coordination, material procurement tracking, production information visualization, and the generation of various operational reports for the automotive company, its customers, or its partners.

The manufacturing execution system receives production orders from the ERP system based on customer demand, divides them by components for procurement and production, and manages them throughout the manufacturing process. Furthermore, the AVEVA Select APU MES solution updates the status of each order in the ERP system, enabling real-time order tracking. It also manages material tracking for production processes.

Additionally, tracking and tracing the materials used in automotive production is crucial for quality control and supply chain management.

Wonderware Supply Chain Connector is an MES application extension. It provides import and export capabilities in standardized formats to facilitate enterprise integration with AVEVA Select APU MES software through automatic import and export of critical order, material, and performance information.

As the automotive industry continues its evolution from gasoline-powered combustion engines to more efficient and environmentally friendly designs, AVEVA Select APU drives car production as it gains momentum in the electric vehicle market.

Valmet Automotive's Automotive Plants implemented Wonderware MES software solutions to manage their production.

|

|

Objectives

The car manufacturer needed production data to be easily transferred between automation and ERP systems.

They also needed electronic documents to share production information more easily across different departments and company executives.

The data generated through the new automation software system needed to enable effective management of the bill of materials, as well as tracking and tracing of the data used in the manufacturing of final products.

Challenges

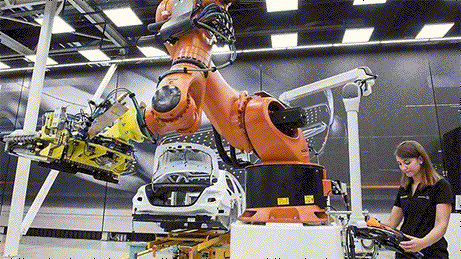

Due to the growing demand for low-consumption electric vehicles, the company wanted to quickly install an MES solution to enable an immediate production acceleration.

It was important for the new software solution to easily integrate with existing software and hardware on-site for a faster return on investment.

Results

The AVEVA solution was quickly installed, allowing Valmet to start production in just three months.

The software provides flexibility in managing production data documents and bill of materials.

With its web-based reporting functionalities, all production managers and relevant executives have immediate access to production data, enabling more effective decision-making.

The AVEVA solution implementation was completed in three months, allowing Valmet to immediately improve production across its various automotive lines.